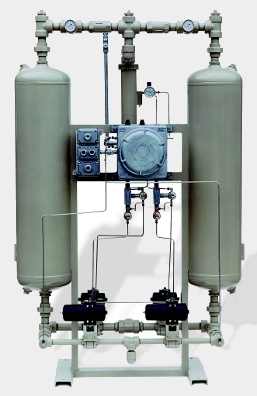

StylAir's SHL Series - More Info

The StylAir regenerative desiccant dryer is a fully automatic unit designed to dry compressed air or gas to meet or exceed the customer's requirements. The dryer consists of dual drying chambers which are alternately cycled through drying and regeneration cycles. One chamber is drying air at all times.

The wet, compressed process air flows through one drying tower where water vapor is adsorbed into the desiccant - an inert, hygroscopic material with an enormous surface to mass ratio. The off-stream drying tower is regenerated by taking a small amount of the dried process air (purge) and passing it through its bed at low (atmospheric) pressure. The moisture trapped in the desiccant is released and is carried off by the purge flow and exhausted to atmosphere.

|

Conservative Tower Sizing - Designed for Optimum Performance and Long Desiccant Life

Rugged, Reliable Industrial Controls

Standard corrosion resistant acrylic coating protects for years in adverse environments |

ASME code designed and stamped drying towers on all floor models SS Desiccant Support/Flow Distributors

Proven high reliability valving

Separate desiccant fill and drain ports on all models (exc. SHL-H01N and SHL-H03N) |